|

Jimo Jinlong Plastic Compound Color Printing Co., Ltd.

|

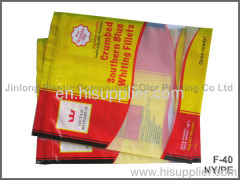

beef jerky packaging bag

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1)vacuum beef jerky packaging bag

2)3-side sealed with zipper

3)material:HGPET/PE

4)w euro-hole,clear window,tear nick

5)w good printing

Features:

1)vacuum beef jerky packaging bag

2)3-side sealed with zipper

3)material:HGPET/PE,vacuum bag

4)w euro-hole,clear window,tear nick

5)with 1 cm side seal and bottom seal

2)3-side sealed with zipper

3)material:HGPET/PE,vacuum bag

4)w euro-hole,clear window,tear nick

5)with 1 cm side seal and bottom seal

6)great printing can be up to 12 colors

Food bag/food packaging bag/freezing bag/boiling bag

1. Customized structure, size, style and printed design are welcome.

2. Structure: PET/ AL/ PE with longest shelf life; matt OPP/ AL/ PE; PET/ VMPET/ PE;

matte OPP/ VMPET/ PE; PET/ VMPET-PET/ PE allow clear window in one side;

PET/PE and NY/PE are for transparant bags.

3. Style: stand up with zipper bag, three side sealed bag, Quad-sealing bags.

4. Print: Rotogravure to 12 colors, attractive designs. Customers printing designs or logos available.

5. Suit for shopping, stores and home.

6. Waterproof and recyclable material, environment friendly.

7. Supply period:all the year round

About Jinlong Plastic Compound Color Printing Co., Ltd.:

We are a professional manufacture of various plastic bags, with more than 14 years experience in this line. The two factories locate at beautiful 2008 Olympic Sailing city Qingdao and has the nature advantage in the economic geography. It only takes 50 minutes to Qingdao Port and 20 minutes to Qingdao International Airport.

Certificates available for your information on your request:

SGS international verification and authentication

Business Certificate

Import and Export Licence

ISO 9001:2008 ISO14001:2004

Factory Audit Report

2002/72/EC

94/62/EC

The main products we produce

1) Food bags for coffee or coffee beans, spices, sauces, meat, frozen food, pet food,seafood, juice, noshes, etc, nearly including all kinds of foods

2) Commodity bags for commodities, such as washing powder, pool powder

3) Garment bags, mainly for underwear, socks, T-shirts

4) Carrier bags with handles, ropes, or hanger hole

5) Styles available: stand up, zipped, heat-sealed, heat-cut, cold-cut, blown, sealed-in the-middle, three-side-sealed, with handle or hanger hole

Brief production and capacity introduction:

We control and choose the excellent suitable raw materials from our suppliers, and make the design mature by our professional designer. Then the order come into the substantial production stage. We have the full set of advanced equipments including the 3 layers coex extruding machines, 12-color computer controlled printings, Japanese printing-inspection machines, dry lamination machine, high speed slitting and folding machines and bag-making machines for wide range style and size bags. The production capacity has been increased largely since we ran our 2nd factory. Additionally our normal flexible management make the everything go quite orderly to achieve the best performance.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!